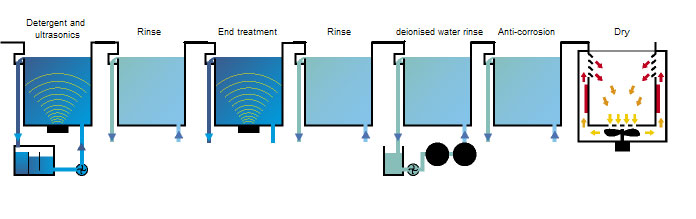

U7M. 7 stages from 15 to 180lThis is an aqueous process which is applicable to a wide range of products. Parts are transferred through a number of open tanks, the first of which contains a low concentration of detergent as the main cleaning agent. This range of machines is particularly suitable for steel components since the last tank contains a corrosion protection product. Application :Removal of oil, grease, particles, polishing paste, grinding paste… Metallic machined, pressed or cast components, in particular steel Principal of operation :

Standard cleaning cycle :

U7M30 machine with robot and load/unload conveyors Technical specifications (printable version) |